English

English

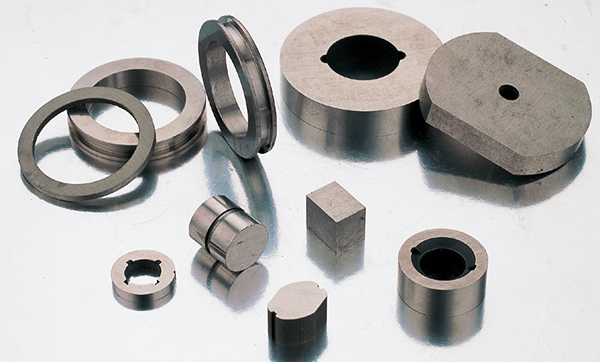

Location : Home > Product

| Magnetic and Physical Properties of Cast Alnico Magnet | |||||||||||||

| Grades |

Equivalent MMPA |

Remanence |

Coercive Force |

Maximum Energy Product |

Density |

Reversible Temp. Coefficient |

Reversible Temp. Coefficient |

Curie T emp. |

Temp. Coefficient |

Remark | |||

| Class | Br | Hcb | (BH)max | g/cm3 | α(Br) | α(Hcj) | TC | TW | |||||

| mT | Gs | KA/m | Oe | KJ/m3 | MGOe | %/℃ | %/℃ | ℃ | ℃ | ||||

| LN10 | ALNICO 3 | 600 | 6000 | 40 | 500 | 10 | 1.2 | 6.9 | -0.03 | -0.02 | 810 | 450 | Isotropy |

| LNG13 | ALNICO 2 | 700 | 7000 | 48 | 600 | 12.8 | 1.6 | 7.2 | -0.03 | 0.02 | 810 | 450 | |

| LNGT18 | ALNICO 8 | 580 | 5800 | 100 | 1250 | 18 | 2.2 | 7.3 | -0.025 | 0.02 | 860 | 550 | |

| LNG37 | ALNICO 5 | 1200 | 12000 | 48 | 600 | 37 | 4.65 | 7.3 | -0.02 | 0.02 | 850 | 525 | Anisotropy |

| LNG40 | 1250 | 12500 | 48 | 600 | 40 | 5 | 7.3 | ||||||

| LNG44 | 1250 | 12500 | 52 | 650 | 44 | 5.5 | 7.3 | ||||||

| LNG52 | ALNICO 5DG | 1300 | 13000 | 56 | 700 | 52 | 6.5 | 7.3 | |||||

| LNG60 | ALNICO5-7 | 1350 | 13500 | 59 | 740 | 60 | 7.5 | 7.3 | |||||

| LNGT28 | ALNICO 6 | 1000 | 10000 | 57.6 | 720 | 28 | 3.5 | 7.3 | -0.02 | 0.03 | 850 | 525 | |

| LNGT36J | ALNICO 8HC | 700 | 7000 | 140 | 1750 | 36 | 4.5 | 7.3 | -0.025 | 0.02 | 860 | 550 | |

| LNGT38 | ALNICO 8 | 800 | 8000 | 110 | 1380 | 38 | 4.75 | 7.3 | -0.025 | 0.02 | 860 | 550 | |

| LNGT40 | 820 | 8200 | 110 | 1380 | 40 | 5 | 7.3 | -0.025 | 860 | 550 | |||

| LNGT60 | ALNICO 9 | 900 | 9000 | 110 | 1380 | 60 | 7.5 | 7.3 | -0.025 | 0.02 | 860 | 550 | |

| LNGT72 | 1050 | 10500 | 112 | 1400 | 72 | 9 | 7.3 | -0.025 | 860 | 550 | |||

| Sintered AlNiCo Typical Magnetic Properties | |||||||||||

| Grade | Remanence | Coercivity |

Intrinsic Coercivity |

Max. Energy Product |

Density | Working | Remark | ||||

| Temp | |||||||||||

| Br | Hcb | Hcj | (BH)max | Tc | |||||||

| KGs | T | KOe | Ka/m | KOe | Ka/m | MGOe | Kj/m3 | g/cm3 | ℃ | ||

| FLN8 | 5.2 | 0.52 | 0.5 | 40 | 0.54 | 43 | 1.0-1.25 | 8月10日 | 6.8 | 760 | Isotropic |

| FLNG12 | 7 | 0.7 | 0.5 | 40 | 0.54 | 43 | 1.5-1.75 | 12月14日 | 7 | 810 | |

| FLNGT14 | 5.7 | 0.57 | 0.95 | 76 | 0.98 | 78 | 1.75-2.0 | 14-16 | 7.1 | 850 | |

| FLNGT18 | 5.6 | 0.56 | 1.1 | 88 | 1.13 | 90 | 2.25-2.75 | 18-22 | 7.2 | 850 | |

| FLNG28 | 10.5 | 1.05 | 0.58 | 46 | 0.59 | 47 | 3.5-4.15 | 28-33 | 7.2 | 850 | Anisotropic |

| FLNG34 | 11 | 1.1 | 0.63 | 50 | 0.64 | 51 | 4.3-4.8 | 34-38 | 7.2 | 890 | |

| FLNGT28 | 10 | 1 | 0.7 | 56 | 0.71 | 57 | 3.5-3.8 | 28-30 | 7.2 | 850 | |

| FKNGT31 | 7.8 | 0.78 | 1.3 | 104 | 1.13 | 90 | 3.9-4.5 | 31-36 | 7.2 | 890 | |

| FLNG33J | 6.5 | 0.65 | 1.7 | 135 | 1.88 | 150 | 4.15-4.5 | 33-36 | 7.2 | 850 | |

| FLNGT38 | 8 | 0.8 | 1.55 | 123 | 1.58 | 126 | 4.75-5.3 | 38-42 | 7.2 | 850 | |

| FLNGT42 | 8.8 | 0.88 | 1.5 | 120 | 1.53 | 122 | 5.3-6.0 | 42-48 | 7.25 | 850 | |

E-mail:cary.li@ss-magnet.com

Copyright © 2019 Ningbo Southern Strong Magnet Industry Co.,Ltd.