Sintered NdFeB Magnet

Known as the third Generation of Rare Earth Magnets, Neodymium-Iron-Boron(NdFeB) magnets are the most powerful and advanced commercialized permanent magnets today. NdFeB magnets are introduced in 1980. This material offers the highest Energy Product (BH)max commercially available. Today their typical applications include high performance sensors, various DC motors, linear actuators, MRI, wind energy turbines etc. The highest (BH)max reaches up to 51MGOe. The choice of strip casting and HDDR technology in our factory allow us to make high performance NdFeB over N52 possible. The intrinsic coercive force is over 30000Oe. Also, magnets are protected with effective surface treatment to prevent corrosion.

|

TYPICAL PROPERTY |

|

MAGNETIC CHARACTERISTICS |

|

PROPERTIES |

BrmT (KGs) |

Hcb KA/m (Koe) |

Hcj KA/m (KOe) |

(BH)max KJ/m³ (MGOe) |

Max.TW ℃ |

|

GRADE |

|

N33 |

1130-1170 (11.3-11.7) |

≥836 (≥10.5) |

≥955 (≥12) |

247-263 (31-33) |

80 |

|

N35 |

1170-1210 (11.7-12.1) |

≥868 (≥10.9) |

≥955 (≥12) |

263-287 (33-36) |

80 |

|

N38 |

1210-1250 (12.1-12.5) |

≥899 (≥11.3) |

≥955 (≥12) |

287-310 (36-39) |

80 |

|

N40 |

1250-1280 (12.5-12.8) |

≥923 (≥11.6) |

≥955 (≥12) |

302-326 (38-41) |

80 |

|

N42 |

1280-1320 (12.8-13.2) |

≥923 (≥11.6) |

≥955 (≥12) |

318-342 (40-43) |

80 |

|

N45 |

1320-1380 (13.2-13.8) |

≥876 (≥11.0) |

≥955 (≥12) |

342-366 (43-46) |

80 |

|

N48 |

1380-1420 (13.8-14.2) |

≥835 (≥10.5) |

≥876 (≥11) |

366-390 (46-49) |

80 |

|

N50 |

1400-1450 (14.0-14.5) |

≥796 (≥10.0) |

≥876 (≥11) |

382-406 (48-51) |

60 |

|

N52 |

1430-1480 (14.3-14.8) |

≥796 (≥10.0) |

≥876 (≥11) |

398-422 (50-53) |

60 |

|

N35M |

1170-1220 (11.7-12.2) |

≥868 (≥10.9) |

≥1114 (≥14) |

263-287 (33-36) |

100 |

|

N38M |

1220-1250 (12.2-12.5) |

≥899 (≥11.3) |

≥1114 (≥14) |

287-310 (36-39) |

100 |

|

N40M |

1250-1280 (12.5-12.8) |

≥923 (≥11.6) |

≥1114 (≥14) |

302-326 (38-41) |

100 |

|

N42M |

1280-1320 (12.8-13.2) |

≥955 (≥12.0) |

≥1114 (≥14) |

318-342 (40-43) |

100 |

|

N45M |

1320-1380 (13.2-13.8) |

≥995 (≥12.5) |

≥1114 (≥14) |

342-366 (43-46) |

100 |

|

N48M |

1360-1430 (13.6-14.3) |

≥1027 (≥12.9) |

≥1114 (≥14) |

366-390 (46-49) |

100 |

|

N50M |

1400-1450 (14.0-14.5) |

≥1033 (≥13.0) |

≥1114 (≥14) |

382-406 (48-51) |

100 |

|

33H |

1130-1170 (11.3-11.7) |

≥836 (≥10.5) |

≥1353 (≥17) |

247-271 (31-34) |

120 |

|

35H |

1170-1210 (11.7-12.1) |

≥868 (≥10.9) |

≥1353 (≥17) |

263-287 (33-36) |

120 |

|

38H |

1210-1250 (12.1-12.5) |

≥899 (≥11.3) |

≥1353 (≥17) |

287-310 (36-39) |

120 |

|

40H |

1240-1280 (12.4-12.8) |

≥923 (≥11.6) |

≥1353 (≥17) |

302-326 (38-41) |

120 |

|

42H |

1280-1320 (12.8-13.2) |

≥955 (≥12.0) |

≥1353 (≥17) |

318-342 (40-43) |

120 |

|

45H |

1300-1360 (13.0-13.6) |

≥963 (≥12.1) |

≥1353 (≥17) |

342-358 (43-46) |

120 |

|

48H |

1370-1430 (13.7-14.3) |

≥995 (≥12.5) |

≥1353 (≥17) |

358-390 (46-49) |

120 |

|

33SH |

1130-1170 (11.3-11.7) |

≥844 (≥10.6) |

≥1592 (≥20) |

247-272 (31-34) |

150 |

|

35SH |

1170-1210 (11.7-12.1) |

≥876 (≥11.0) |

≥1592 (≥20) |

263-287 (33-36) |

150 |

|

38SH |

1210-1250 (12.1-12.5) |

≥907 (≥11.4) |

≥1592 (≥20) |

287-310 (36-39) |

150 |

|

40SH |

1240-1280 (12.4-12.8) |

≥939 (≥11.8) |

≥1592 (≥20) |

302-326 (38-41) |

150 |

|

42SH |

1280-1320 (12.8-13.2) |

≥987 (≥12.4) |

≥1592 (≥20) |

318-342 (40-43) |

150 |

|

45SH |

1320-1380 (13.2-13.8) |

≥1003 (≥12.6) |

≥1592 (≥20) |

342-366 (43-46) |

150 |

|

28UH |

1020-1080 (10.2-10.8) |

≥764 (≥9.6) |

≥1990 (≥25) |

207-231 (26-29) |

180 |

|

30UH |

1080-1130 (10.8-11.3) |

≥812 (≥10.2) |

≥1990 (≥25) |

223-247 (28-31) |

180 |

|

33UH |

1130-1170 (11.3-11.7) |

≥852 (≥10.7) |

≥1990 (≥25) |

247-271 (31-34) |

180 |

|

35UH |

1180-1220 (11.8-12.2) |

≥860 (≥10.8) |

≥1990 (≥25) |

263-287 (33-36) |

180 |

|

38UH |

1220-1250 (12.2-12.5) |

≥876 (≥11.0) |

≥1990 (≥25) |

287-310 (36-39) |

180 |

|

40UH |

1240-1280 (12.4-12.8) |

≥899 (≥11.3) |

≥1990 (≥25) |

302-326 (38-41) |

180 |

|

28EH |

1040-1090 (10.4-10.9) |

≥780 (≥9.8) |

≥2388 (≥30) |

207-231 (26-29) |

200 |

|

30EH |

1080-1130 (10.8-11.3) |

≥812 (≥10.2) |

≥2388 (≥30) |

223-247 (28-31) |

200 |

|

33EH |

1130-1170 (11.3-11.7) |

≥836 (≥10.5) |

≥2388 (≥30) |

247-271 (31-34) |

200 |

|

35EH |

1170-1220 (11.7-12.2) |

≥876 (≥11.0) |

≥2388 (≥30) |

263-287 (33-36) |

200 |

|

38EH |

1220-1250 (12.2-12.5) |

≥899 (≥11.3) |

≥2388 (≥30) |

287-310 (36-39) |

200 |

|

N40EH |

1250- 1280(12.5- 12.80) |

>=939(>=11.8) |

>=2388(>=30) |

302-326(38-41) |

200 |

|

N42EH |

1280- 1320(12.8- 13.2) |

>=955(>=12.50) |

>=2388(>=30) |

318-350(40-44) |

200 |

|

N45EH |

1320- 1360(13.2- 13.6) |

>=955(>=12.50) |

>=2388(>=30) |

342-366(43-46) |

200 |

|

N48EH |

1360- 1400(13.6- 14.0) |

>=1026(>=12.90) |

>=2388(>=30) |

366-390(46-49) |

200 |

|

N30AH |

1080- 1130 (10.8- 11.3) |

>=804(>=10. 1) |

>=2786(>=35) |

223-255(28-32) |

220 |

|

N33AH |

1130- 1170 (11.3- 11.7) |

>=836(>=10.5) |

>=2786(>=35) |

247-271(31-34) |

220 |

|

N35AH |

1180- 1220 (11.8- 12.2) |

>=860(>=10.8) |

>=2786(>=35) |

255-287(32-36) |

220 |

|

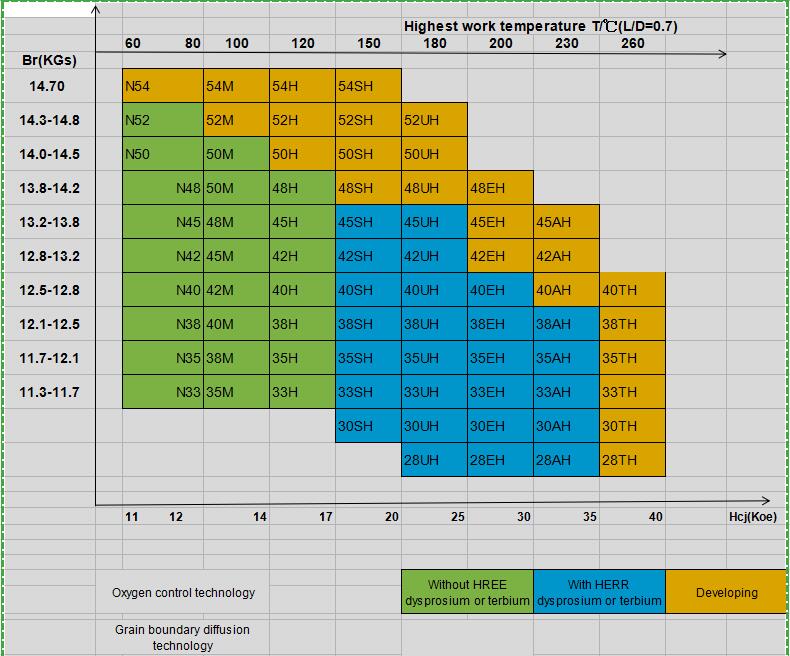

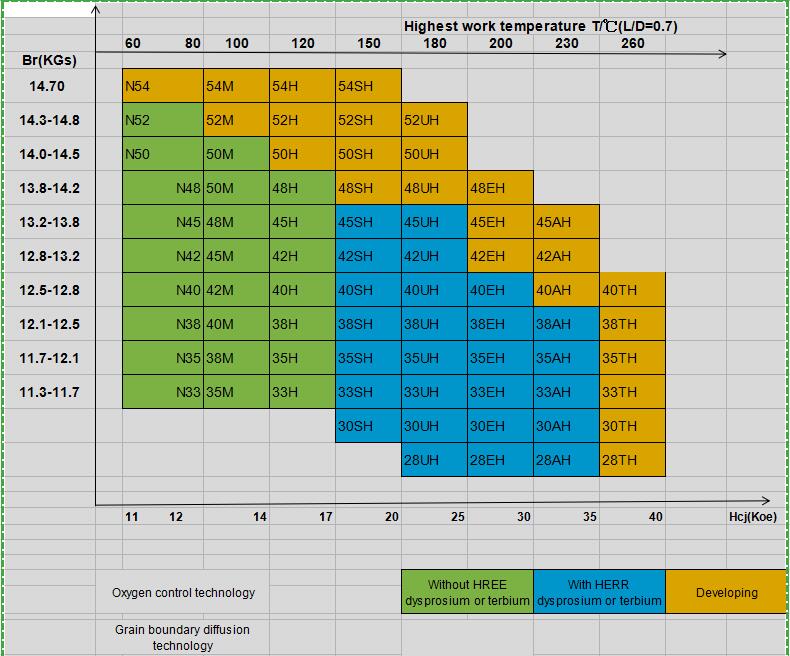

Characteristic Comparisons |

|

Grade |

N |

M |

H |

SH |

UH |

EH |

AH |

|

Max.TW |

80℃ |

100℃ |

120℃ |

150℃ |

180℃ |

200℃ |

250℃ |

|

Property |

Low |

High |

Higher |

|

Supperior high |

Extremely high |

Highest |

|

Hcj Value |

>=11KOe |

>=14KOe |

>=17KOe |

>=20KOe |

>=25KOe |

30>=11KOe |

>=35KOe |

* The above-mentioned data of magnetic parameters and physical properties are given at room temperature.

* The maximum service temperature of magnet is changeable due to the ratio length and diameter and environmental factors.

* Density: 7.4~7.6g/cm³; αBr: -0.09~-0.13%/℃; αHcj: -0.50~-0.80%/℃ ; Hardness: Hv 600 ;

|

Surface |

Coating |

Colour |

Thickness(μm) |

Standard Resistance |

Corrosive Resistance |

|

PCT Test |

Salt Spray Test |

|

Nickel |

Nickel |

Silver |

10-20 |

48hr or 72hr |

72hr |

EXCELLENT |

|

Ni+Cu+Ni |

|

Zinc |

Blue Zinc |

Bright Blue |

8-20 |

24hr |

24hr |

GOOD |

|

Colour Zinc |

Shinny Colour |

|

Epoxy |

Epoxy |

Black / Grey |

15-25 |

48hr |

96hr |

EXCELLENT |

|

Ni+Cu+Epoxy |

|

Tin |

Ni+Cu+Sn |

Silver |

15-20 |

72hr |

72hr |

SUPERIOR |

|

Parylene |

Parylene |

Grey |

15-25 |

96hr |

200hr |

SUPERIOR |

|

Teflon |

Teflon |

Grey |

10-20 |

12hr |

24hr |

SUPERIOR |

|

Phosphorization |

/ |

Grey |

1-2 |

- |

- |

TEMPORARY PROETCTION |

|

Passivation |

/ |

Grey |

1-2 |

- |

- |

TEMPORARY PROETCTION |

|

* PCT test(120℃,100%RH,2.0atm);Salt Spray Test(5%NaCl,35℃ continue spray). |

|

Item |

Parameters |

Reference Value |

|

Additional |

Temp.Coeff.of Br (α(Br))/(%/K) |

-0.08 ~ -0.12 |

|

Temp.Coeff.of Hcj (β(Hcj))/(%/K) |

-0.42 ~ -0.70 |

|

Curie Temperature (Tc)/K |

310 ~ 380 |

|

Recoil Permeability (μrec)[-] |

1.05 |

|

Mechanical |

Density (g/cm³) |

7.6 |

|

Vickers Hardness (Hv) |

650 |

|

Electrical Resistivity (μΩom) |

1.4 |

|

Compressive Strength (Mpa) |

1050 |

|

Tensile Strength (Mpa) |

80 |

|

Bending Strength (Mpa) |

290 |

|

Thermal Conductivity (W/(moK)) |

6 ~ 8 |

|

Young's Modulus (Gpa) |

160 |

|

Coefficient of Thermal Expansive (C⊥) (10-6/K) |

-1.5 |

|

Coefficient of Thermal Expansive (C‖) (10-6/K) |

6.5 |

|

* Technical specifications and parameters are subjected to change without notice. |

Customized Shape and coatings:

Block:

Disc&Cylinder:

Ring:

Segment:

Other shape: